“CARTON BOX” ALTERNATING CARTONING MACHINE

This is our CARTON BOX, a cartoning machine made for an important company that, with a series of machines sold and installed in the Brazilian market, gave us the opportunity to expand our production range and enter in to other product sectors.

Six machines have been working for eighteen months in three shifts, at an American multinational company working in the confectionery sector, and four others were supplied last February to another Brazilian customer. The prototype has been in production in Germany for over two years at a chewing-gum company.

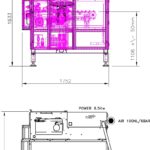

With the CARTON BOX we have created a “horizontal cartoning machine in economic version” able to cover the speed band up to 60 cycles per minute. Prepared to receive customized automatic feeds, it is suitable for treating various sectors, including cosmetics and pharmaceuticals, tubes, bottles, sticks, envelopes and parallelepiped products in general.

Designed for flat blank cardboard, it has been conceived with such characteristics that it has allowed us to realize without any difficulty the completion to treat pre-glued cartons, integrating only the closing of the interlocking flaps.

At the moment we have two movies, made by customers and both users for solution from blank that you can view on the links:

http://youtu.be/y6XPxQ_w6k4

APPLICATIONS OF USE

In order to face a market that is increasingly aimed at containing prices, we are inspired by some principles used on vertical cartoning machines, naturally respecting the classic functions of the intermittent motion horizontal machine.

The CARTON BOX, extremely simple and small, offers some innovative solutions that characterize it and give it greater flexibility in handling the case.

For the low price it is also in competition with the manual loading vertical cartoning machines.

The execution of the balcony, with a simplified format change, is powered by “brushless” motors for the main movements and by pneumatic drives for the secondary connections.

The wide range of sizes allows to treat even medium-sized products.

The primary material used:

- Siemens for the electrical part;

- Festo for the pneumatic part;

- Lenze for brushless motors and related drivers.

Made for pre-glued boxes with interlocking closure and alternating flaps / airplane, the CARTON BOX is equipped with a series of options normally required by the market.

To define the price of the complete and working CARTON BOX we considered it necessary to divide it into two distinct parts:

Basic machine suitable for picking-forming-filling-closing of the case;

Product feeding with relative transport to the introduction station in case.

Currently we have made two different feeds: for pre-grouped sticks and wrapped cookie bars, both made on the machines currently in production.

We are planning other power supplies for the following applications:

Squeezed tubes in monofilament on tape;

Cylindrical and non-cylindrical flasks with propeller tipping;

Parallelepiped products such as soaps, sticks, bins, all on tape.

PARTICULAR PRODUCTS

For products that are difficult to accumulate, the machine is set to work in an electric axis (gearing) with the upstream packaging machine.

Complete the structure of the CARTON BOX, in addition to the different power supplies, some optional accessories, normally used for this type of machine:

Additional format;

Collection group and pre-filled instruction insertion;

Case closure with hot glue;

Warehouse cartons lengthened and served by motorized conveyor belt;

Dry case coding or by INKJET;

Swivel console with pulse button and touch screen display.

We have created a first draft of a leaflet complete with technical and dimensional data of the machine.